We are excited to announce the publication of two new articles which discuss different aspects of high Reynolds number wind turbine wakes. Check them out here: https://fluids.psu.edu/publications/.

Wind Tunnel Pressure Vessel Delivery

We are excited to release a compilation video covering the delivery of our new compressed air wind tunnel pressure vessel.

Be sure to check us out on our socials: @MillerFluidsLab

New Wind Tunnel Pressure Vessel has Arrived

We are excited to announce the delivery of our new high pressure vessel which is the core element of our compressed air wind tunnel. The vessel itself arrived in five different sections totaling a combined 50 tons. Allison Crane and Rigging handled the vessel offloading and placement. We are now focused on getting the facility operational, more updates to come.

High Pressure wind tunnel in place.

Aligning and bolting up vessel sections.

Unloading the main chamber section from the flatbed trailer.

Moving in the first section of the pressure vessel.

New publication on Vertical Axis Wind Turbine performance at field-relevant conditions

We are excited to announce the recent publication in Flow Journal of our work on Vertical Axis Wind Turbines (VAWTs) and how the solidity (the “solidness” of the turbine, or ratio of blade surface area to swept area) affects the performance of these machines at field-relevant conditions (i.e. very high Reynolds numbers, using a compressed air wind tunnel). Check it out on our publications page or via the open-access Flow Journal here: cambridge.org/core/journals/

Compressed Air Wind Tunnel Fabrication

We have received some new images from the manufacturer of our pressure vessel, with the four elbows in various states of assembly. These images put into perspective the scale of the new facility. We will have more updates coming soon.

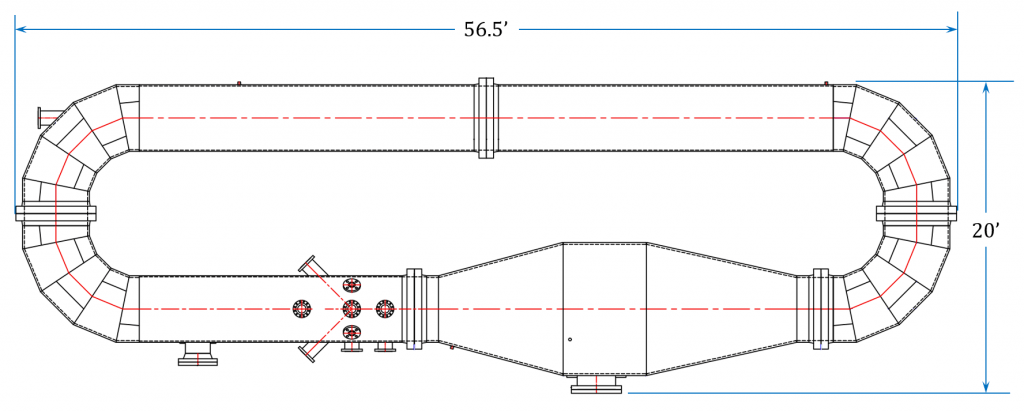

Compressed Air Wind Tunnel: The Pressure Vessel

The main component of our new wind tunnel facility is the pressure vessel shell. The facility has been designed to optimize size while achieving moderately high pressures to create the ideal environment for testing at high Reynolds numbers. With a pressure rating of 500 psi, we can achieve 34 times the atmospheric density of air, and only minor increases in the viscosity.

Our facility is also large, with a maximum test section size of 40″ in diameter, meaning we can test relatively large models at very high Reynolds number values, approaching 1 million per inch.